Packing Machine using LLDPE stretch film

Overview:

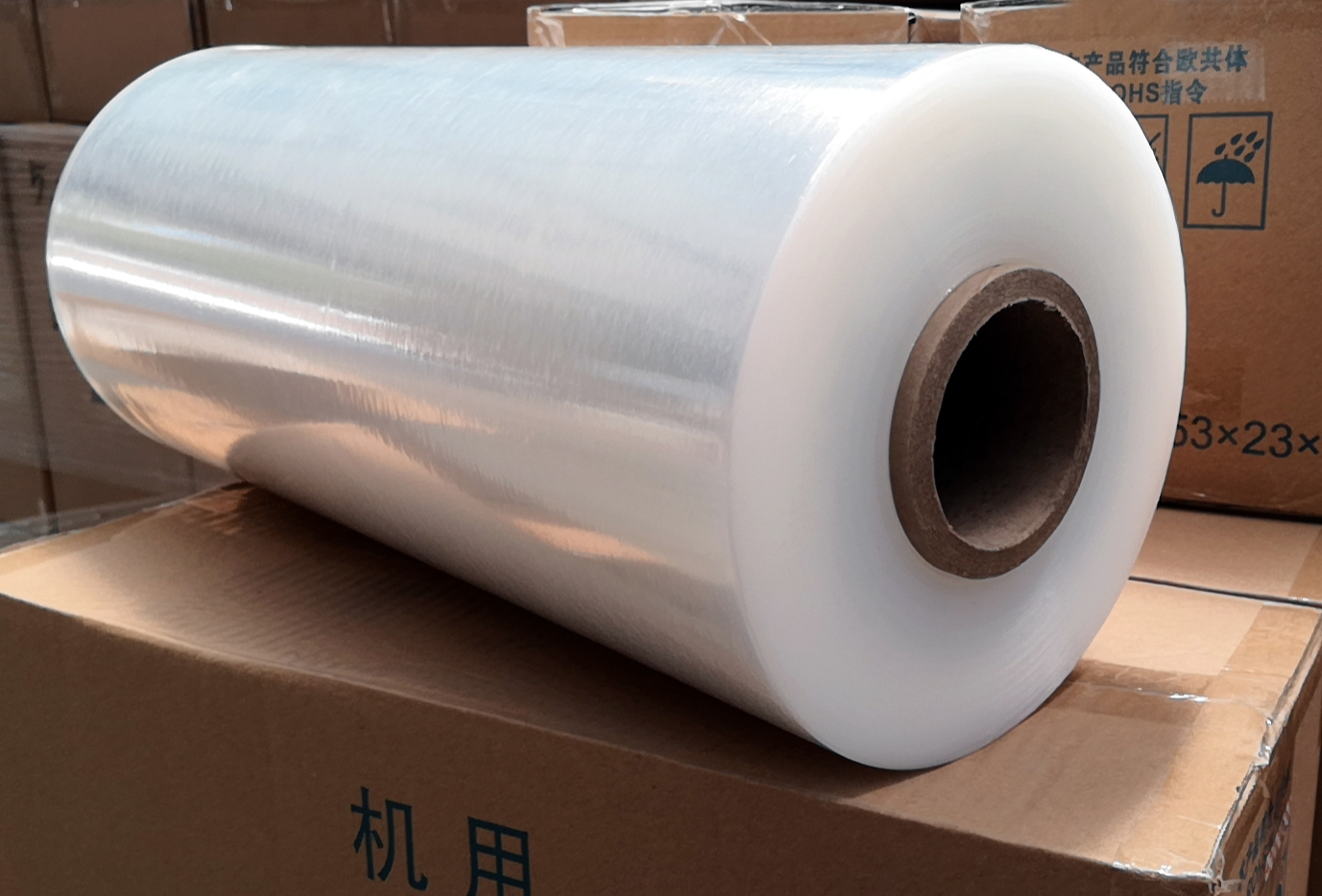

Machine stretch wrap is mainly used for Semi Automated and Fully Automated Stretch Machines. Machine grade stretch film has high pre-stretch capability. Suitable for various irregular loads.

Xinzhihui LLDPE cast machine stretch film is more suitable for applications with automatic wrapping machines, which have high performance and widely used in FMCG industry, electronic products, paper making, logistics, chemicals, building materials and glass,etc to save labour cost and time cost and material cost.

We have unique formula to meet our customers requirement on different performance, like stronger stretch elongation or high viscosity. The popular thickness of machine stretch film is 15Um, 18Um and 20Um.

Feature:

Type: Casting

Hardness: soft

Transparency: transparent

Features: moisture-proof

Processing Type: Casting

Specification:

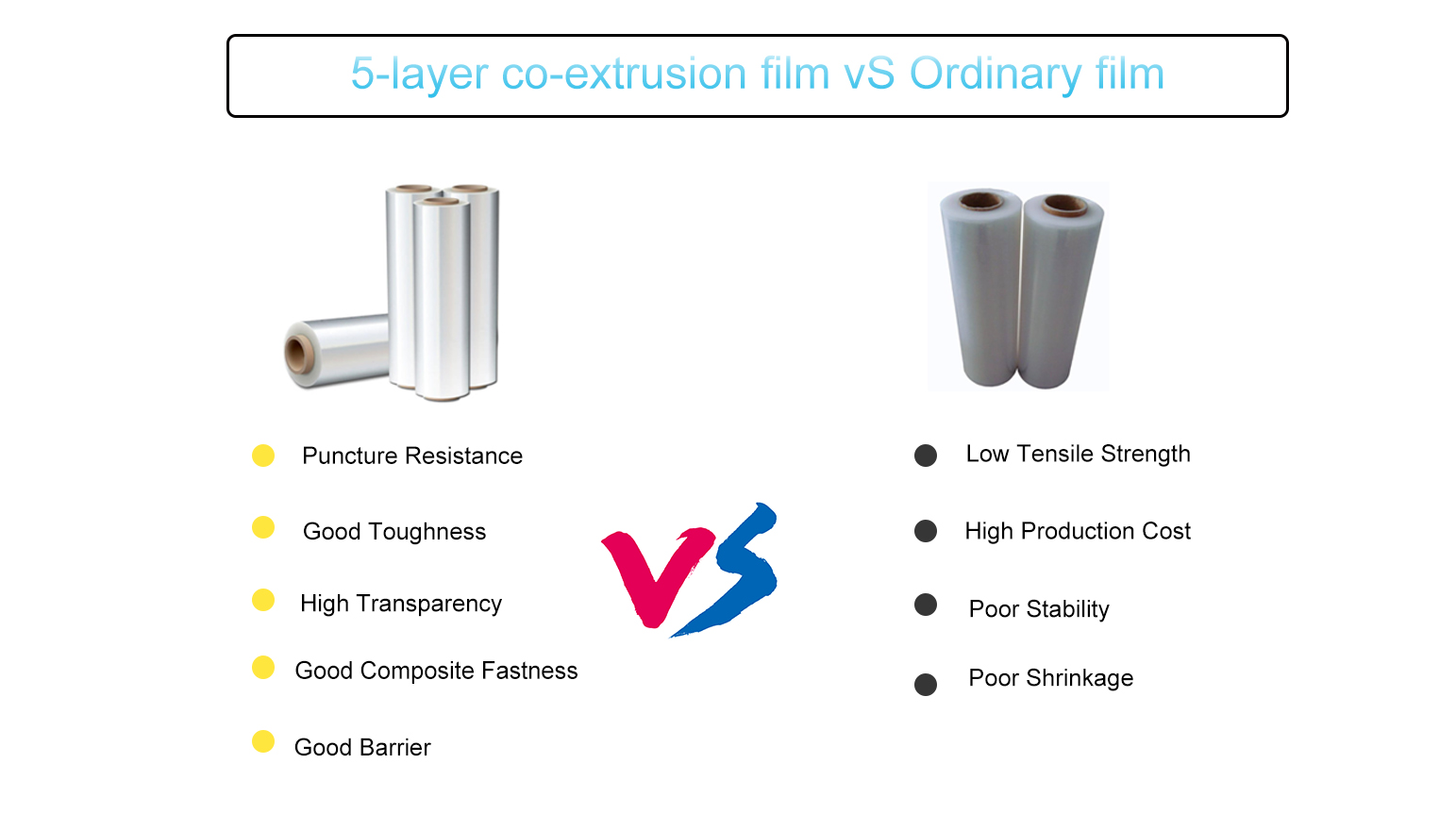

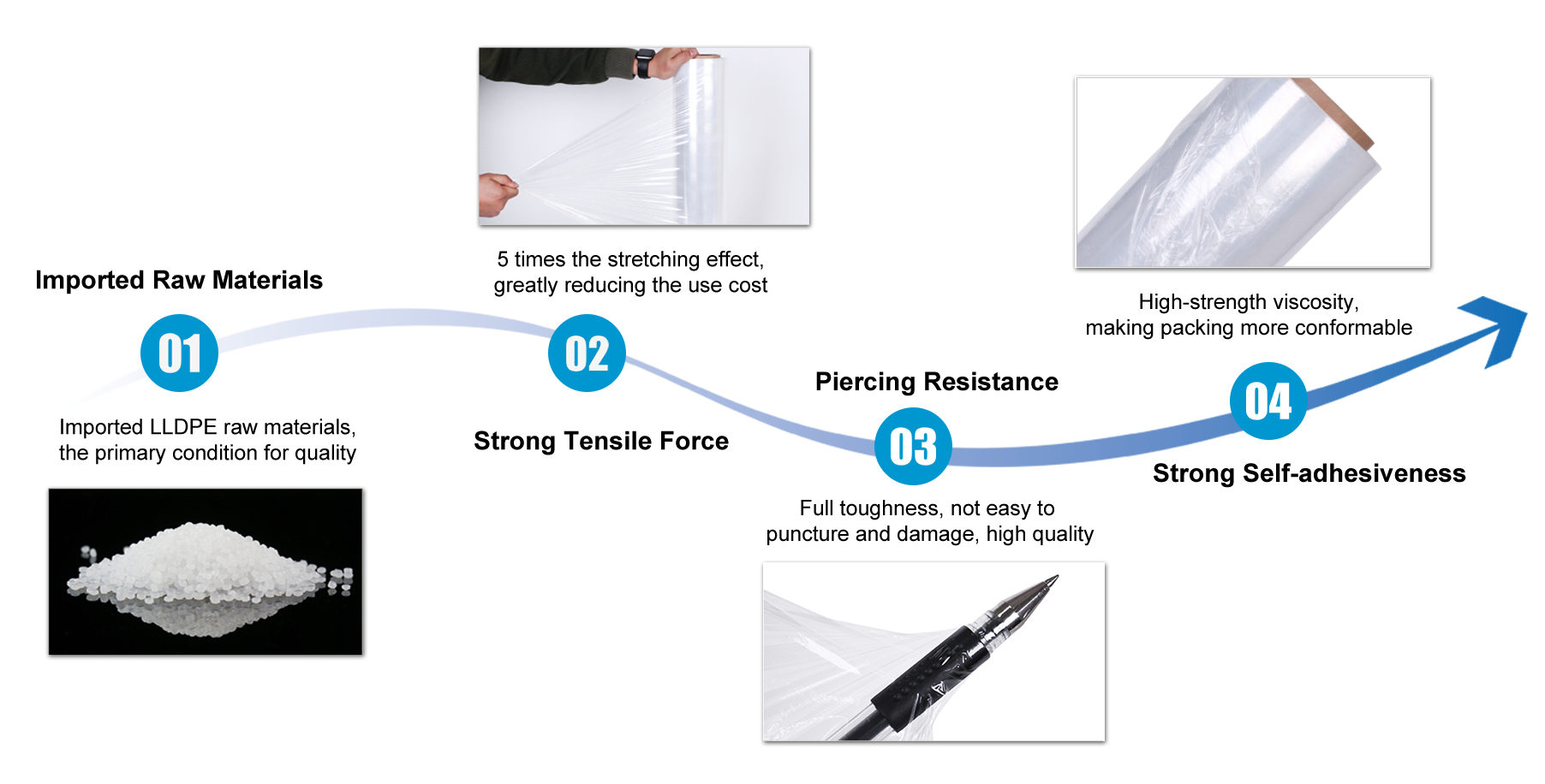

Xinzhihui stretch film have excellent elongation and the stretch ratio can reach to 300-500% while the elongation of ordinary stretch film is only about 150%-250%, our stretch film can help you saving up to 30-50% material.

1, 500mmx18mic,16kg (500mmx72gauge,≈1932meters≈6339ft)

2, 500mmx20mic,16kg (500mmx80gauge,≈1739meters≈5705ft)

3, 500mmx23mic, 16kg (500mmx92gauge,≈1512meters≈4961ft)

4, 500mmx25mic,16kg (500mmx100gauge,≈1391meters≈4564ft)

Package: 1roll/ctn, 2rolls/ctn, 4rolls/ctn, 6rolls/ctn,nude packing and according to customers’ requirement.

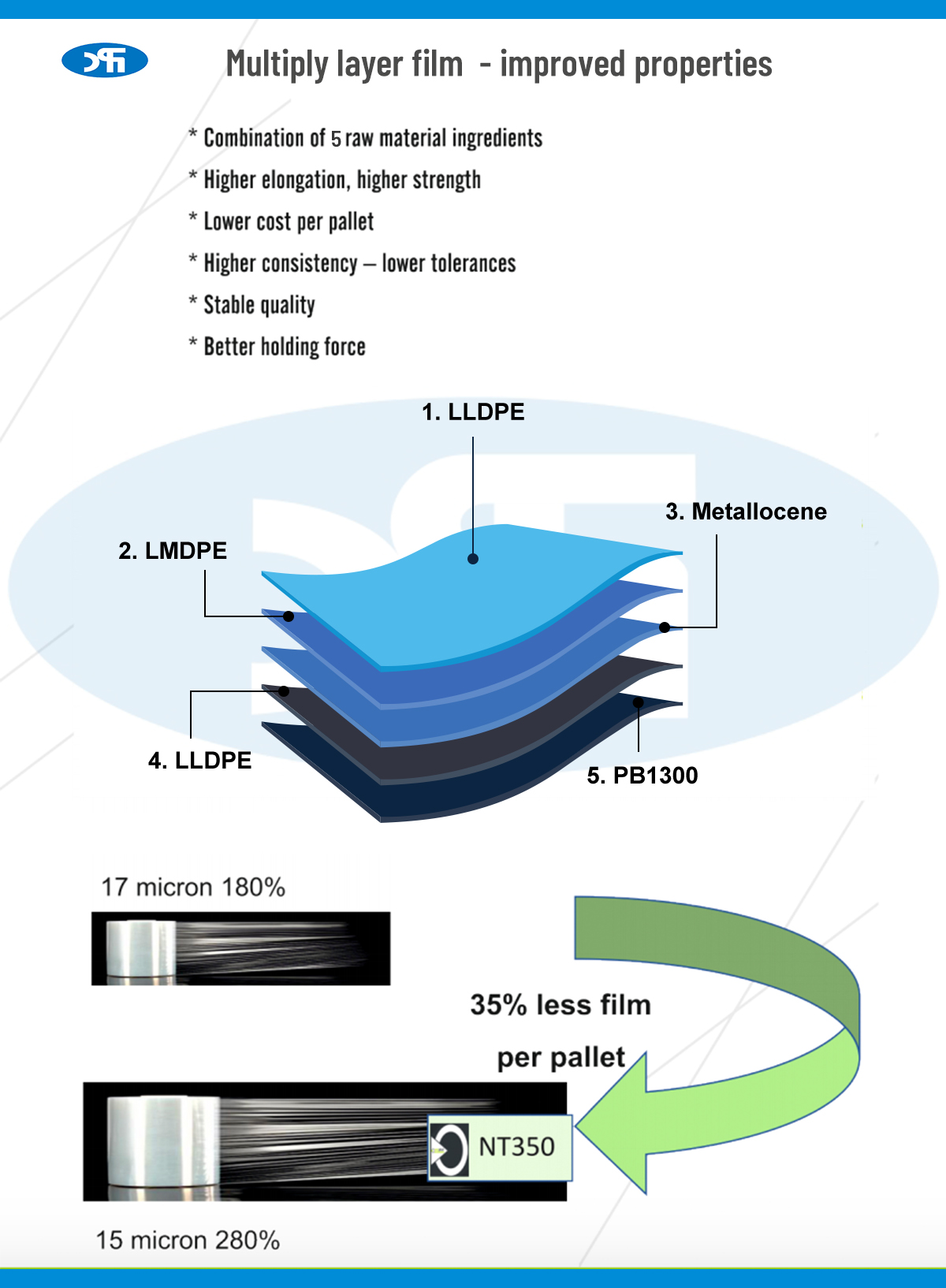

Processing technology: Casting 3-5 layers co-extrusion process.

Stretch rate: 300%-500%.

Delivery time: Depends on quantity and detail requirement, normally 15-25days after receive deposit, 7-10 day for a 20’ container.

FOB Shipping Port: YANTIAN, SHEKOU , SHENZHEN

Output: 1500 Tons per month.

Category: Hand grade and machine grade.

Advantage: Waterproof, moisture-proof, dust proof, strong gird structure, anti-collision high transparency, high adhesiveness, high extensibility, reduce resource consumption and total cost of ownership.

Certificates: ISO9001, ISO14001, REACH, RoHS, Halogen approved by SGS.

| Thickness | 12mic--50mic (12mic, 15mic, 17mic, 18mic, 19mic, 20mic, 23mic, 25mic, 30mic are very common sizes) |

| Width | 75mm, 76mm, 100mm, 125mm, 150mm, 200mm, 300mm, 400mm, 450mm, 500mm, 760mm, 1.0m |

| length | any length under customers' requirements |

| Production method | casting method with 3-5 layers machine |

| output | 1000 tons per month |

| Category | hand grade and machine grade |

| Factory capacity | 2 big production machines for Jumbo Roll, 20 rewinding machines for small rolls |

| Maximum weight | 45kg net weight in 500mm width, 60kg in 1.0m width |

| Stretch Ratio | 300% ~600% |

| Paper core | laminated paper core. 0.4kg, 0.5kg, 0.6kg, 0.7kg,1 kg, 1.5kg |

| Special ones | bundling stretch film with handles can be offered,( 58272738,3" paper core)mini roll stretch film(1" plastic core)pre-stretch wrapped film |

| Certificates | ISO 9001:2008, REACH, RoHS approved by SGS |

| Samples | Free samples can be offered as your requirement |

| Advantages | strong gird structure, economical, laboratory tested, efficient, high extensibility, resistant to low temperatures, puncture resistance, etc. |

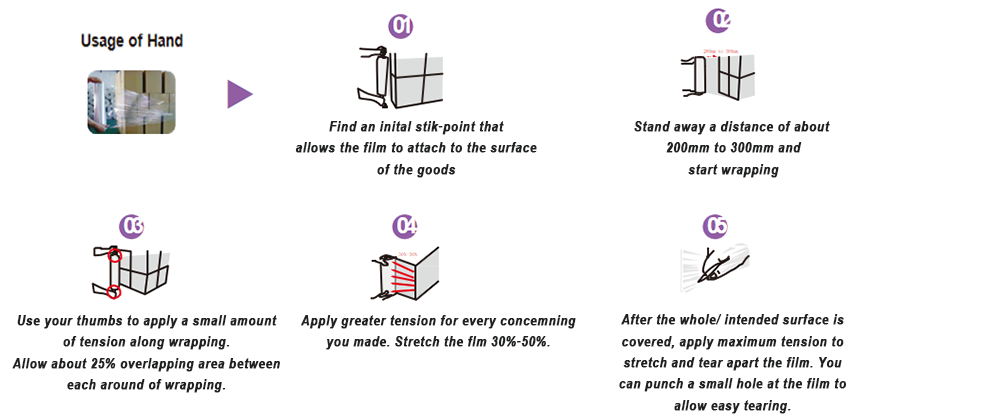

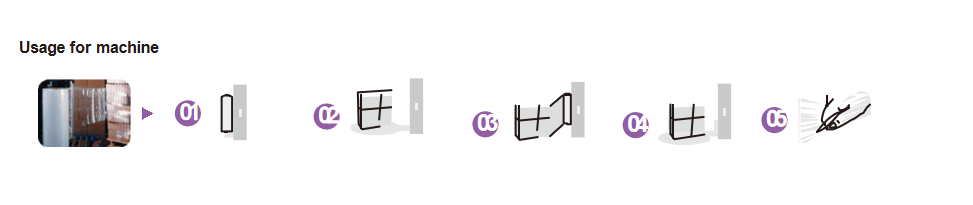

Instructions for use:

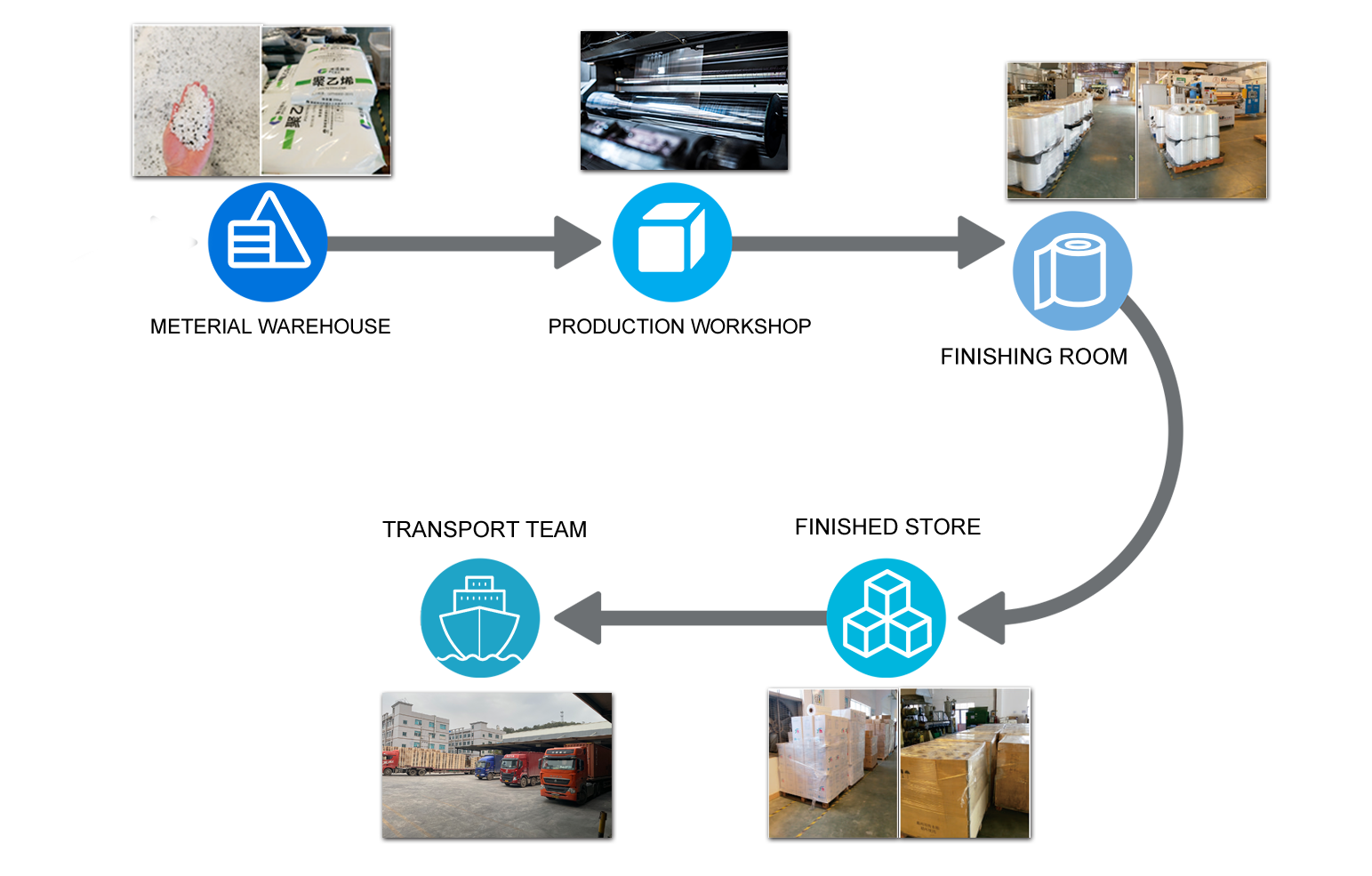

Production process:

product testing:

Packing and shipping: